Junction boxes are installed on the backside of photovoltaic (PV)

panels and serve to protect electric components from environmental

elements. To improve junction box mounting and protect integral

components, a solar panel manufacturer was exploring ways to

decrease costs, improve manufacturing efficiency, and meet panel

lifetime expectations.

CHALLENGE

The customer was looking for the most efficient and consistent way

to pot their solar panel junction boxes. It was paramount that they

found a reliable solution that would protect the ribbon wire

connection from corrosion as well as protect against moisture

ingress through the back panel. In addition, the potting materials

had to seal and adhere to a variety of substrates including a

plastic junction box, metal ribbon wires, and the glass back panel.

SOLUTION

KPD-700 is an automatic silicone dispensing station for j-box. The unit

includes an XY robot for silicone/glue dispensing and a conveyor

belt for j-box transportation. The system eliminates all the errors

typically faced in manual or semi-automatic sealant applications.

The system ensures consistent sealant dispensing and helps to cut

down on wastage or residue, lowering the production costs. This

sealing solution can be adapted to various types and models of

j-boxes.

Machine picture

Machine description and working principle

Compound materials A & B are kept in two tanks separately. There are two sets of

metering pumps inside the machine for metering A and B resin by setting ratio, draining out material individually from tank A & B. Liquid A & B mix with each other in

the mixer pipe and dispensed out according to the programmable

data.

Machine Breif introduction

1. The whole bucket of glue only be placed on the tank side of the

machine, and the equipment can be automatically extracted without

manual pouring into the storage bucket.

2. The storage tank can be customized according to the potting of

AB glue in each hour.

3. The storage tank has automatic defoaming function and material

location level detection function.

4. The tank can be customized according to your glue need, such as:

automatic stirring, automatic constant temperature, air drying,

etc. ..

5. High-precision screw pump (gear pump / plunger pump) pushes glue

through the cavity, with high pressure and fast glue output.

6. The servo motor drives the screw pump , the speed of each pump

can be set separately, to keep the flow speed of each pump, To

achieve the required mixing ratio (1: 1--1: 10 adjustable).

7. Equipped with dynamic mixing device to make the mixing of glue

more uniform.

8. Equipped with automatic cleaning function, no need to manually

cleaning the machine, avoid manual cleaning trouble.

9. Equipped with 500 * 500mm mechanical arm, which can edit the

running path, To actual perfect potting ab glue at correct location

on product

Options:

1.Dispensing with Dozing nozzle or Static mixer/dynamic mixer

2.Constant or Variable resin:hardener mixing-ratio

3.Single or Multi Dispenser Potting

4.Fixed or Moveable dosing nozzle (Dispensing)

(X-Y-Z axis movement or interpolation)

5.Automatic Loading & Unloading of Trays

6.Ability to dosing different quantities of raw materials to

different locations in one program

7.Automation: pre-heating and curing oven with conveyor

8.Extra degassing tanks for uninterrupted production

Dosing Pumps

1. Very precise even at very low volumes

2.Constant mixing ratio ensures faultless dosing

3. Metering pumps ensures minimal amounts of reactive mix

4.Temperature controlled design

5. Resistant to abrasion even when filled with high abrasive

casting resins and does not require maintenance

Machine Vacuum Tank Agitator

1. Full homojenization

2.No sedimentation

3. Perfect degassing

Static Mixer /dynamic mixinng

1.Perfect homogenization without dead space

2. Abrasion resistant & low maintanence

3.Temperature controlled design

4. Ensures optimal viscosity of reactive compounds at constant

temperature

5.Provides very long service life with a closed cleaning system

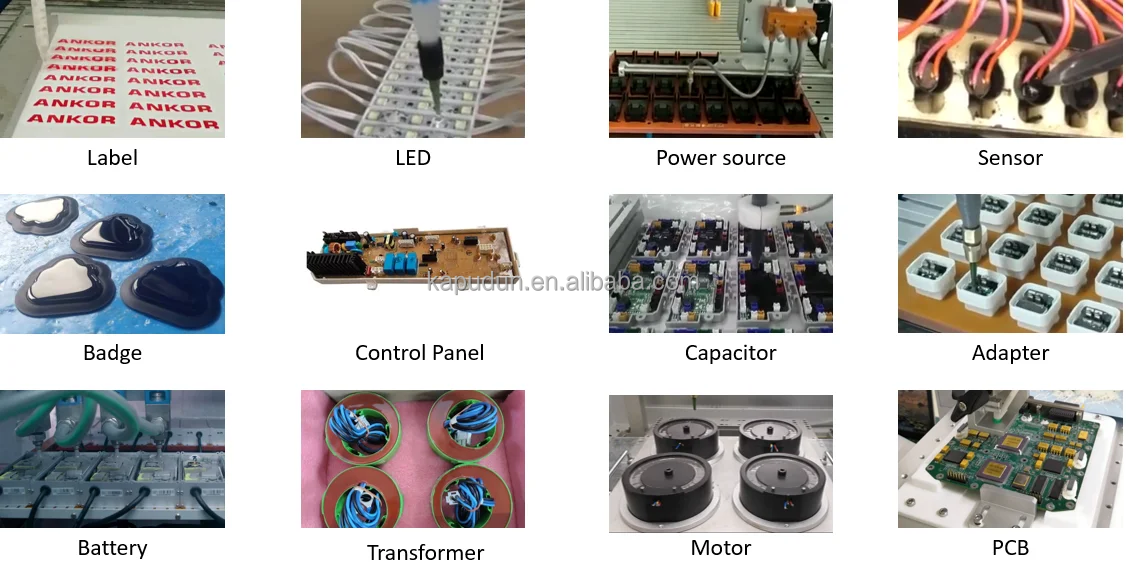

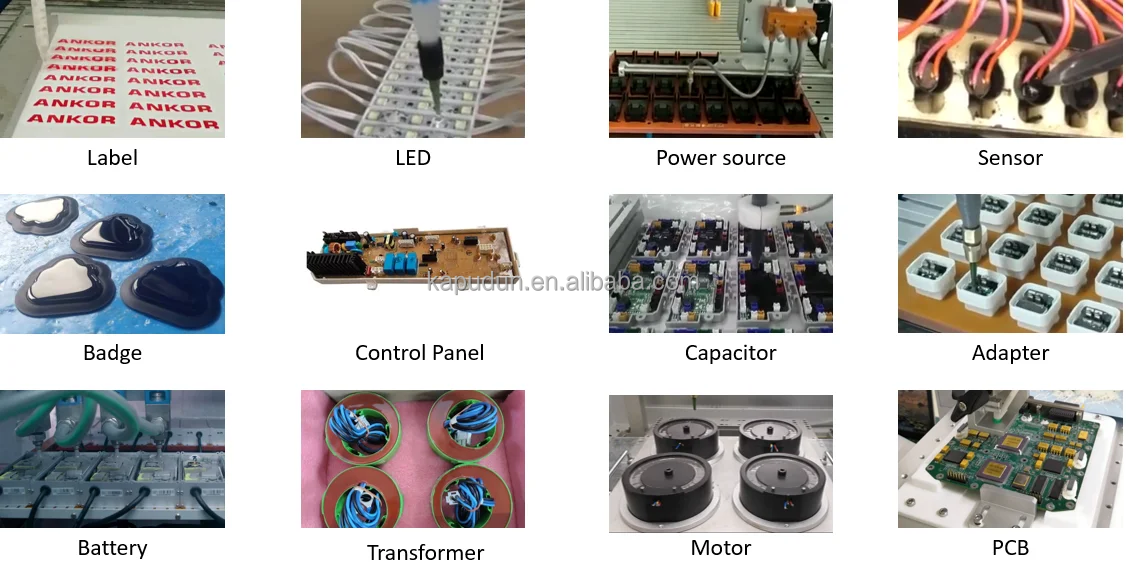

Applications:Potting&isolation &Casting: electronics componnets , PCB board, Capacitor, power supply, transformer, ignition coil, reverse sensor,

circuit board, filter products ,underwater parts, electronic ballast ,aviation parts, aerospace parts....Dispensing&Dosing : LED strip , led lamp , led bulb , aluminum,led screen , display module ,medical parts,medical liquid filling ....

Bonding&doming : LCD screen ,LOCA bonding,ABS plastic,different types of stickers , badge , keychains , souvenirs ,arts , photo frame , and other arts graphics....

Transformer , capacitance , power module , regulating plate

,protection module , generator , pressure package , soli relay

,fault indicator , Sensors , junction box , clutch , wave filter ,

water meter , boattery cover , rectifier and so on ...

Suitable Material

1K and 2-component polyurethanes, epoxies, acrylics, silicones,

temperature, humidity and UV curing materials.Two component potting materials , 2-part compound materials, AB part compound materials , 2K silicones ,2K epoxies resin, Bi-component PU, Ployerster, Polyurethane, UV materials and so on .