| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Supply Ability : | 50 Piece/Pieces per Month |

| Price : | $ 8500/pieces >=1 pieces |

| Delivery Time : | 5-8 days |

| Payment Terms : | T/T 、Western Union、Money Gram |

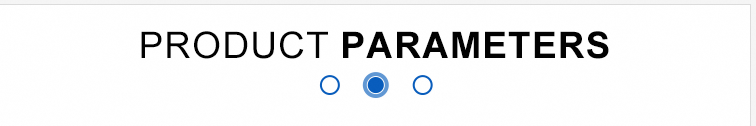

Models: | KPD-500 Automatic Multifunctional Glue Potting Machine | ||||||

Suitable process | it can be used as a stand-alone machine or with the customer's

originaassembly line to achieve on-line gluing. | ||||||

Proportion of glue. | 10:1 - 1:1 | ||||||

Hybrid approach: | Dynamic stirring mixing/static | ||||||

Machine Stroke: | 500x500x100mm | ||||||

Speed: | XY axle 400mm/s | ||||||

Accurate: | +0.05mm | ||||||

Programme stock: | 999 | ||||||

programmer: | Teach-In Programming | ||||||

metrological: | High precision metering pumps | ||||||

control method: | PLC+touchscreens | ||||||

input method: | Touch screen + buttons + IO | ||||||

Appearance Material: | Industrial square tube welding + 6061 alloy + cold rolled plate | ||||||

Drum size: | A barrel 30L, B barrel 10L (can be customised) | ||||||

External Dimensions. | 1100x1350 X1600mm | ||||||

Gum flow rate. | 1-80g/5sec (customised large glue volume available) | ||||||

trajectory: | Punching points, walking straight lines, curves, drawing circles,

arcs, squaresand other irreqular shapes. | ||||||

Supply Voltage | AC220V/50HZ | ||||||

|